Everything you need to know about wire rope hoists and chain hoists, especially in the field of lifting and hoisting technology.

Everything about our professional LED lighting technology for vehicle lighting.

Did you know?

As a manufacturer and distributor of electric winches, hydraulic winches, hoists, generators and automotive LED lighting, we have almost everything immediately available and in stock, which guarantees you a high availability and very short delivery times!

A small selection of winches

Even we as a professional and manufacturer cannot give a 100% blanket answer to this, as the actual pulling load depends on many factors, such as the motor/, hydraulic power, the type of gear, the size of the drum and of course the object you want to move. All our winches have an indication of the pulling/ & lever load in (T) tons or (K) in kilograms.

The actual value in T or K you can then move will also depend on where you are using your winches. For example, if it is firmly attached to the wall or ceiling on a steel beam, you can certainly use the full pulling or lifting force, but if the winch is attached to a vehicle, the maximum pulling force may be significantly reduced due to the weight of your motor vehicle if you want to pull other vehicles or objects towards you. For motor vehicles that you use for towing, for example, you should calculate with a factor of 0.2 to ensure that the other vehicle does not pull you itself.

Example

Your vehicle weighs 3 tons, with the factor 0.2 you can safely move 2.4 tons without slipping yourself. If you have the possibility to attach the winch to the front of the vehicle and use an attachment to the next tree at the back of the trailer hitch, you can extend the factor as far as your vehicle weighs + the maximum towing load of your trailer hitch. So 3T vehicle + 2T trailer hitch = 5T via pulleys or block and tackle these values can be further increased.

If you want to use the winches to get your vehicle out of a predicament yourself, you should choose the factor of about 1.5 if you want to buy a winch. This will ensure that you will not have any problems even if the terrain is uneven.

Example

Your vehicle weighs 3 tons, with the factor of 1.5 you should choose a winch that can pull at least 4.5 tons. With pulleys or special pulley blocks you can increase the power of the winch again significantly.

As you can see, the issue is very dependent on what you want to move with your winch and especially where you want to do it.

Unfortunately, we cannot give a general answer to this question for all winches in the world, but there is a good calculation formula for the operation of electric winches.

Sample

You have an electric winch with e.g. 12V and an electrical connected load of 1KW i.e. 1000Wh and you want to operate this winch on your vehicle. Your winch can consume 1KW per hour from your battery, here it does not help if you run the engine, because your alternator in the car will not be able to absorb this load completely. First we calculate the maximum power of your battery in W = Watt.

12V (x) 65Ah = 780W, since the car battery is never fully charged, let's assume about 80%, leaving about 624W. So we can't operate our winch for a full hour, but that's not necessary, because the regular use is usually only a few minutes. It is important to understand that we have to be careful not to discharge our battery completely, otherwise we will not be able to start the car.

Example peak load

Another important value is the peak load of the battery. Modern car batteries can deliver 4-6 times the electrical power for a certain time. E.g. 200-300Ah, this also happens when starting the engine. Here (Ah) ampere stands for the electrical energy. A car battery should in no case be operated permanently with such a high load, because it then becomes so hot that it can take irreversible damage. In our case, a starter battery is installed that has a permanent load of 90-100Ah. This means that this battery can permanently supply approx. 1080W - 1200W until the battery is empty due to its capacity.

PS. The data for your battery can be found on the battery itself e.g. 12V and the capacity in Ah e.g. 65Ah, if you then still know the model, you can ask on most manufacturer pages of the bacteria the peak loads or view online. In rare cases, this data is also on the battery. The calculation examples also work at 24V, here you only have to change the values.

Conclusion

So before you attach a winch to your vehicle, it is important to first find out if you will be able to supply the necessary amount of power. With a second battery you can increase the capacity of your car if necessary. For this, you should then visit an automotive workshop, as the performance of your alternator is crucial.

Yes, the pulling/ or lifting force of winches can change negatively but also positively due to various factors such as the rope length, the pitch, the angle or the drum size.

Rope length

The longer the rope, the greater the leverage effect on the winch will be, but you will hardly notice any difference if the pulling power is set at 90° and the steel rope is 10-30 m long. In general, it is also advisable not to pull the object to be pulled at an angle, but always as straight as possible, this is related to the drum. If you use, for example, a pulley to change the angle or use a bottle hoist, the pulling/lifting force can increase again significantly, because this is also possible.

Gradient / Slope

The slope or angle at which the rope is wound onto the drum or the object is pulled can also affect the pulling force. A greater slope increases the pulling force, for example, if the object is higher than the winch (Positive slope) or on the opposite side also negative, with a (Negative slope), if something is lower than the winches. We all know this, because a tire rolls down the hill but not up.

Drum size

The size of the drum can also affect the pulling force or lifting force. A larger drum can wind more rope, but will cause the power to decrease. A smaller drum has a smaller radius and cannot take as much rope, but can move proportionally more mass (tons) depending on the winch specifications.

Important

However, it is important to note that these factors cannot be considered independently and are also dependent on other factors such as the power of the winch and the condition of the rope. As you can see, it is anything but easy to answer. If in doubt, ask our team for advice.

This is difficult to answer, because it depends on what you want to use the winch for and whether it is mobile or stationary. In general, however, the whole thing can be divided into three areas.

A good rope, whether made of synthetic fibers or a steel cable, a good pulley or a hook/shackle that you can use to attach the load or, if necessary, a remote control around which you can expand their winch. In addition, there are of course other accessories such as jacks, mounting plates, covers, rope windows or other miscellaneous accessories that can be interesting for a winch depending on the application, for this you are welcome to look around in our store or ask our nice staff.

Each winch has different important features and there are many data that you should definitely pay attention to when buying a winch. One of the most important values is of course the pulling or lifting force, this is usually given in LB (commercial weight), and can be converted into kilograms or tons. In our article descriptions you will always find the kilograms or tons, as this is the simpler specification for most customers.

Depending on the winch, the size of the drum and thus the maximum unwindable rope length is also very important. Smaller winches, for example, 15 to 25 m is the norm. The motor power is also important, i.e. how much power does the motor or winch need to be able to move the heavy loads. The power specifications are given either in horsepower or in KW, i.e. for kilowatts. Other important values are whether the winch has a freewheel, for manually pulling out the rope, the gear ratio and how the winch brakes, whether manually or dynamically.

Important values at a glance (sample)

Pulling force: 1,2T

Rope: 15m Ø 4mm steel

Motor: 0.8 hp / 1.2 kw 24 V

Freewheel: Yes, to pull out the rope manually

Gear ratio: 153:1

Brake: dynamic

Two complicated technical terms, but individually they are easy to explain and in combination can provide an unbeatable result in tractive effort.

In-line motor

Let's start with the motor. Most electronic winches use a so-called series-wound motor, these motors are characterized by a high starting torque, which means that a peak load can be achieved even at low speeds, and the power that is transmitted plays an immense role. At higher speeds, classic motors also achieve a high force, but not as high as with a series-wound motor, which can develop its full potential right from the start.

Planetary gearboxes

A planetary gearbox is a gearbox that can significantly increase the transmission of torque, as well as the increase of torque, these gearboxes are more complex and different in design than normal gearboxes. Moreover, the planetary gearbox allows changing the transmission ratio without separating the power flow. It is characterized by very high efficiency and long service life.

Pulling / & lifting technology

For any application and situation, taking into account the load, safety and other requirements, we have Winch Industry, always the right product for you in stock. So that you do not buy the wrong winch, we look forward to hearing from you by phone or mail.

A small selection of lifting equipment

Even we as a professional and manufacturer cannot give a 100% blanket answer to this, as the actual pulling load depends on many factors, such as the motor/, hydraulic power, the type of gear, the size of the drum and of course the object you want to move. All our hoisting winches have an indication of the lever load in (T) tons or (K) in kilograms.

The actual value in T or K that you can then move will also depend on where you are using your hoist winch. For example, if it is permanently attached to the ceiling on a steel beam, you can certainly use the full lifting force, but if the hoist is attached to, say, wooden beams or just bolted into the ceiling, the maximum pulling force may be significantly reduced.

Generally, however, loads of 20 or 50T are no problem, depending on the model. In addition, there are also even larger models.

This is difficult to answer, because it depends on what you want to use the hoist for and whether it is mobile or stationary. In general, however, the whole thing can be divided into three areas.

A good steel cable, if necessary a good pulley or a hook/shackle that you can use to attach the load or, if necessary, a remote control around which you can expand their winch. In addition, there are of course other accessories that can be interesting for a hoisting winch depending on the application, for this you are welcome to look around in our store or ask our friendly staff.

Each hoisting winch has different important features and there are many data that you should definitely pay attention to when buying a hoisting winch. One of the most important values is of course the lifting force, this is usually given in LB (commercial weight), and can be converted into kilograms or tons. In our article descriptions you will always find the kilograms or tons, as this is the simpler specification for most customers.

Depending on the hoisting winch, the size of the drum and thus the maximum rope length that can be unwound is also very important. Smaller hoisting winches have most its rope length of, for example, are 5 to 10 m. Also important is the motor power, i.e. whether purely electric or hydraulic or even a chain hoist in manual mode. The specifications for the power of hoisting winches are given either in horsepower or in KW, i.e. for kilowatts. Other important values are whether the hoisting winch has a freewheel for manually pulling out the rope, the gear ratio and how the hoisting winch brakes, whether manually, magnetically or dynamically.

Important values at a glance (sample)

Lifting force: 4T

Rope: 10m Ø 20mm steel

Motor: 5 kw 230 V

Freewheel: No

Gear ratio: 180:1

Brake: dynamic & magnetic

Two complicated technical terms, but individually they are easy to explain and when combined can provide an unbeatable result in lifting power.

In-line motor

Let's start with the motor. Most electronic hoisting winches use a so-called series-wound motor, these motors are characterized by a high starting torque, which means that a peak load can be achieved even at low speeds, and the power that is transmitted plays an immense role. At higher speeds, classic motors also achieve a high force, but not as high as with a series-wound motor, which can develop its full potential right from the start.

Planetary gearboxes

A planetary gearbox is a gearbox that can significantly increase the transmission of torque, as well as the increase of torque, these gearboxes are more complex and different in design than normal gearboxes. Moreover, the planetary gearbox allows changing the transmission ratio without separating the power flow. It is characterized by very high efficiency and long service life.

A small selection of generators

Unfortunately, no. You cannot use every generator to feed into your home grid, for example, to reduce the power load or to continue supplying power to all appliances in the house in the event of a power outage. There are very special generators that have an ATS box and a corresponding switching system that automatically switches over in the event of a voltage drop from the grid operator. Important, depending on the generator model, is also the shift load capability.

Please read more about this under the topic, "What does shift load capability mean".

However, there is an exception for feeding into the house grid. If you are working completely self-sufficiently, i.e. if you do not have a fixed power connection and no other power sources are connected, you can usually connect the generator three-phase to your house in order to supply it with power. Since this case is very rare and occurs exclusively in the outdoor area, you should consult an electrician beforehand.

This is not quite so easy to explain. For this, you must first distinguish between 230 volts and 400 volts. A sliding load capability is always important if you want to feed three phases from your generator e.g. from the power socket or via a direct connection (ATS-BOX) to your generator into the house in case of e.g. a power failure. Normally, the power sockets, which are available with, for example, 16 or 32 amperes (Ah), are designed for equal consumption on each individual phase. These individual current-carrying conductors are called L1 L2 L3 in electrical engineering and are loaded symmetrically, (offset by 120°) in the case of a circular saw connection, for example, which is not a problem here then.

By feeding the current into the house net, however, basically unbalanced loads arise, this is on the one hand because the phases L1 L2 L3 e.g. are not divided symmetrically in the house and on the other hand it is because not all consumers in the house e.g. the washing machine the television, the stove or the refrigerator, as well as a water boiler are distributed symmetrically on the lines. So it can happen that you are working in the kitchen and therefore the line L1 is heavily loaded, but the other lines L2 and L3 are hardly loaded, because they are in the living room and do not require any power in the bedroom at the moment. Skew- or inclined-load capable generators recognize this and regulate the speed or the loads automatically via control electronics, which prevents excessive revving of the motor.

The question is quickly answered with a no. The smaller models in particular are not suitable for unbalanced loads, as they only monitor one phase of the three-phase connection. This is not a problem for normal operation of e.g. circular saws or other electronic devices that require three-phase current and consume it symmetrically, but it is not advantageous for the connection to a house and in the worst case it can lead to overrevving of the motor because the phases are then loaded unevenly.

For generators that only have 230 volt connections, there is no sliding load capability, as this only applies to three-phase connections, i.e. whenever phases L1 L2 L3 are used.

First of all, we need to take a close look at the voltage specifications. Colloquially, the voltages 230 volts and 400 volts have become common. From a technical point of view, however, this is not always entirely correct. The network operators are required to keep the voltages between 220 and 230 volts or 380 and 400 volts.

So what voltages does a generator have? That depends entirely on the model in question, smaller generators usually do not have three-phase connections that operate at 380 or 400 volts. The smaller models are therefore operated exclusively with 220 to 230 volts. The larger models then usually have both voltages. In addition to these specifications, it is still important to understand that if the loads are too high, a generator can no longer handle them, we are talking about peak loads and it can then happen that the voltage collapses.

This happens whenever you connect a load to your generator that has a higher power than your generator can deliver at the connection, a nice example is a table saw with 4 kW and you use a generator with 3 kW.

If you want to read more about loads and peak loads, look here further down in the FAQ.

This is quickly explained. Generally, engine-driven generators have a so-called idle speed, which is the speed that is present when no consumer is connected, here the voltage ranges should always be between 220 and 230 volts, and 380 and 400 volts. If a consumer is now connected to the generator, you will notice that the generator automatically increases its speed. It does this to provide more power. When a consumer decreases power, the voltage in the generator usually decreases, and the generator automatically compensates for this by increasing its speed. The control electronics and monitoring within the generator then regulates the number of revolutions.

In the case of smaller generators, this can cause very large voltage fluctuations, for example when starting an electric lawn mower or other tools such as drills. Larger generators have a so-called voltage equalization for this. You may know this from the audio sector, where capacitors in large bass loudspeakers ensure that when a lot of energy is needed, this is fed from the temporarily stored capacitors, as a so-called buffer.

Large generators have this buffer, this ensures that the voltage does not fluctuate too much and the engine can increase its speed smoothly. In some generators you will also find inverters. These inverters work on a similar principle and control the output voltage for their consumers that you want to connect to the generator. Likewise, the control electronics regulate the mains frequency that is output at the connection points. The frequency should be between 50 and 52 Hz, no large tolerances are allowed here, otherwise serious damage can occur to the end devices.

Must still be entered!

Since there are different generator types, they are also started differently. Smaller generators usually have a so-called starting rope, which you know from the lawn mower, for example. Here you pull the rope until the alternator generates enough voltage to trigger an ignition spark at the spark plugs.

In the case of diesel units, ignition is initiated by compressing the fuel; if necessary and depending on the outside temperature, there are still glow plugs that are brought up to temperature to enable ignition of the fuel. With these two models, however, there is also the possibility of an E-Start's, provided that a battery is installed and the engine or the generator was manufactured for this type of start. A conversion from a manual start engine to an E-Start engine is usually not possible.

There are also very special models that have an e-start, but start without a battery, here a certain voltage and current is generated by means of a crank, which can then be used to start the engine afterwards. The situation is similar with generators that run on gas, for example. Here there are both generators, which run with a battery or a crank. But also the tightening via a corresponding device is possible. So you see there are many different types and ways to start a generator.

If your generator was not shipped with a battery and there is nothing else in the instructions or our online description, you can use a standard car battery to start your generator. If necessary, pay attention to the cold start performance and capacity of the battery you want to use. In general, however, you are always on the safe side with a 45 amp battery and a cold start capacity of about 120 amps. Of course, you can always use a larger battery.

Please keep in mind that if you use a smaller battery for a smaller generator, which is perfectly okay, it may not be able to provide the power you need to start the engine at lower temperatures or when the battery level is low.

For all engines and generators, cold operation at sub-zero temperatures is always difficult, especially if they have been standing in the cold for a long time and the oil is still viscous. Here it is recommended to let the engine warm up very slightly without taking a load, once the engine has warmed up you can use it as usual. However, if the temperature differences are too great, also consider the control electronics on the engine, where condensation can collect if necessary, which in turn can damage the electronics.

Up to what kind of minus temperature you can operate your generator, depends strongly on the used model. Unfortunately, the manufacturers do not give any exact information. In general, however, it should not be a problem to operate your generator at temperatures up to 10 degrees below zero.

For even colder regions and permanent use at sub-zero temperatures, it is advisable to use a different engine oil that is better suited for such temperatures and retains the lubricating properties even at low temperatures.

This is easily explained. A peak load always occurs when you switch on several consumers at the same time, for example, a refrigerator, a stove, a kettle and a vacuum cleaner. Here we generate a so-called short-term peak load, which can also last for a longer period of time, depending on how long we operate the appliances. The small to medium models can't handle peak loads quite as well. The larger models, on the other hand, beyond 10 kW, can handle higher peak loads over a longer period of time without any problems.

When selecting a general door, pay attention to the following values. Continuous power and short-term peak power.

But do not worry, all generators have a speed protection circuit and a temperature sensor that will prevent your generator from being damaged. The starting current is important for a circular saw, for example, even if your circular saw only requires 4 kW, it is quite possible that it can absorb a multiple of this for a very short moment when starting or switching on, we are then talking about e.g. two to three seconds peak load or a starting current of e.g. 6 to 8 kW. Smaller generators often have problems with this. Large generators have appropriate compensation systems and other capacities for this.

In the case of the circular table saw, however, there are also upstream controls that compensate for the high starting current. Modern circular saws, for example, have this control as standard. So when buying a generator, always pay attention to what you want to connect to it and operate, and how high the load can be at peak times and how long this may last.

A small selection of LED headlights

First of all, an LED is not to be compared with a commercial light source, as it is completely different electronically as well as in physics, chemistry, compared to a commercial light bulb, etc.

An LED, short for "Light Emitting Diode", is a semiconductor light source that emits light when electric current flows through it. Unlike conventional light bulbs where a wire is heated to produce light, an LED is made of a semiconductor material such as gallium arsenide or silicon that emits photons when current flows through it, thus producing light. We can't go into the whole physical and or chemical process here, but the LED is excited to glow by the current.

LED's have a much higher efficiency than incandescent lamps because nothing here needs to be heated to glow, brought and thus produce light, but the material itself emits photons or generates vibrations and is thus excited to glow, e.g. O-LED BIO LED's and are therefore more energy efficient and long lasting. They are used in various applications, such as lighting, display panels, electronics, automotive, TV, etc. and many other devices and places.

First of all, an LED used in a motor vehicle, for example, has a significantly longer service life of 50,000h to 100,000h hours, depending on the model, than a standard incandescent bulb. Another factor is the relationship between power and light output. If we compare two 10 watt bulbs, one of which is based on LED technology and the other is a classic incandescent bulb, the LED bulb has a higher light output efficiency by a factor of 5 to 10 or more compared to the energy consumption.

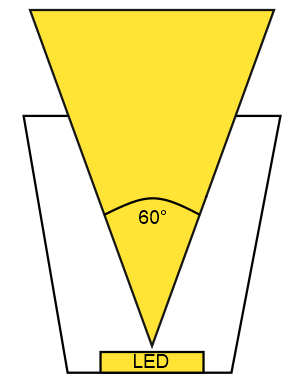

You surely know this from the flashlights of the past with a small light bulb in it. The thrown light cone with a 10 Watt bulb amounts to perhaps 2.5 - 5 m. With an LED, on the other hand, it is already 25 to 50 m. Also, the light thrown purely at the light source of an LED is much more targeted. The light is emitted almost at a 90° angle, which is very effective, especially in the automotive sector for work lighting that is to illuminate a specific area, because the light rays are directed exclusively in one direction and it does not have to be redirected over the body of the entire bulb and housing, there is no stray light, which further increases the perceptible brightness.

A regular illuminant with a light bulb radiates in all directions and just to the front it is often difficult, exactly for this reason car headlights have many mirrors inside the housing to reflect the light as best as possible to the front, but with a well-designed LED this is not necessary at all, because here already from the outset a nearly straight light direction is given. If we now take a look at the light yield in comparison, we see that a 10 watt LED provides about 2.5 times or even more the light output, which in turn means that in our case a much smaller LED with a low wattage would be sufficient. So we could, without any problems, install two five watt LED lights to achieve even higher luminous efficacy in a higher width on our motor vehicle, with the same expenditure of energy, here shows how powerful and economical LED illuminants really are.

In addition, the light colors of LED's can be freely selected according to the manufacturing method. From warm light to cool range, everything is possible here, even red, blue or yellow tones are no problem. Since most LED's emit a relatively cool light, these are ideal for automotive lighting or task lighting.

Most LEDs, including the ones we use, have a regular service life of at least 50,000 hours, some even 100,000 hours. However, these specifications only apply to the installed illuminants and not to the electronics behind them, which is the Achilles' heel of modern LED technology. If you theoretically switch on the LED once in your life, it will certainly shine even far beyond its service life.

The problem is the control electronics in front of the LED. Often there are different power levels here to dim the LED, for example, or to set the volts for the LED down or maybe even out to get it to glow. This control electronics has based on its nature of course also a limit with the switching / and conversion cycles and wears out with each switch on and off and exactly here the electronic component wears out much faster than the actual LED.

The LED does not care how often it is switched on or off or how often currents flow through it or not, only the electronics have an increased wear here. So if you switch your illuminant on or off 2000 or 3000 times every day, the element will say goodbye to active operation well before that, even if the LED inside it, which does the lighting, would still easily manage over 20,000 hours.

This is due to their nature. LEDs are not spherical, but have a flat structure. If you have ever looked at an illuminant that is built on LED technology, you will notice that the actual illuminant is not even fingernail size. The light emitting surface is square and very small and most importantly, flat. The excitation generated by the voltage now ensures that the LED emits photons, i.e. light visible to us, since the LED is flat, the angle of radiation is very straight already almost at 90°, the emitted light is thus already directed by default to almost 100% in one direction, which significantly increases the light yield and the range.

Conventional light sources such as incandescent bulbs radiate in all directions, for this then special housings are needed, which direct the light via mirrors in a certain direction, just look in your headlights at the car.

CREE, Epistar and Brigelux are three different manufacturers of LEDs that may differ in terms of their technology and performance characteristics. The difference between these manufacturers lies in the specific characteristics of their LEDs, such as brightness, efficiency, color accuracy and reliability. Each manufacturer has their own technologies and developments to optimize these characteristics and differentiate themselves from other manufacturers. It is important to note that the performance and quality of LED'S depend not only on the brand, but also on the specific LED series and model.

CREE

CREE is a well-known manufacturer of high-power LEDs based in the USA. Their LEDs are known for their high efficiency, brightness and reliability. CREE LEDs are often used in applications that require high brightness and long life, such as lighting, automotive, and street lighting.

Epistar

Epistar is a Taiwanese LED manufacturer specializing in the production of LED chips and LED packages. Epistar LEDs feature high brightness, energy efficiency, and color accuracy, and are often used in applications such as lighting, displays, and backlighting.

Bridgelux

Bridgelux is a US-based manufacturer of LED chips and LED arrays used in the lighting industry. Their LEDs feature high efficiency and a wide color range, and can be used in a variety of applications.

Not directly, because LEDs simply become weaker and weaker over time and the resistance in the LED becomes higher and higher, which means that at some point it can no longer light up at all because the current does not manage to flow through the LED. However, it can also happen that the control electronics upstream of the LED suffer a defect before the actual LED that is controlled by it fails. In most cases, the control electronics will fail before the LED, well before the life of the actual bulb, you will never see an LED get dimmer because it has gotten too old, before that its control electronics always fail.

But to mention it here again, there are also LED illuminants, which can be controlled directly via e.g. 2V or 6V or e.g. 12V etc.. These are usually very special application-specific high-performance LEDs, which then no longer require a control unit and can be connected directly to the power source, here it may well happen that you can witness the retirement of the LED, but this lasts really very, very long. At a minimum of 50,000h, this is then 5.7 years of continuous use.

LED illuminants can unfortunately not be dimmed simply as it would be the case with standard light bulbs. On the one hand, this is due to the fact that the LEDs are not directly connected to the power source, but usually have control electronics in front of it, which can then no longer work if the voltage is too low, and on the other hand, it can also be directly due to the LED, which is not designed for this and can no longer be stimulated to light up if the voltage is insufficient.

Some manufacturers of LEDs, which we as manufacturers for illuminants in the motor vehicle area install and appropriate control electronics upstream, offer here the possibility of dimming. In this case, it is possible to apply different voltages via the control unit and to output these voltages via the control unit to the illuminant in order to let it shine in a different power level. This can even go so far that the regular voltage is increased in order to increase the luminosity once again, which can lead to the fact that the maximum possible luminous period is reduced from e.g. 50,000 hours to 15,000 hours.

Similarly, if we connect a light bulb to 400 volts instead of 230 volts, it will shine very brightly for a short time, but only for a short time. As you can see, it is possible to design LED technology in such a way that it can be dimmed or even overridden. We are talking here about a 1-2-3 step switching.

A beam angle indicates the angle at which the light source you are using can emit light to the front or side. Since LEDs are generally flat, they have a standard steel angle of about 60° to a maximum of 90° from the center of the LED. This is important to know in order to be able to decide in which area your new work lighting can illuminate the work area, e.g. on your car.

Example

As a rule, unfortunately, no. Due to the assembly of the LED and because most of the components are soldered on a circuit board, it is not possible to repair them. In very rare cases, depending on the model, it may be possible to replace the circuit board if the LED is on an extra circuit board, but this is very rare.

However, if you have ordered, for example, a complete LED socket on which several individual LED lamps are attached, these can of course be replaced, the bulb within this lamp, however, not.

As a manufacturer for automotive LED lighting, we have taken this matter very seriously, as this is often the Achilles heel of LED technology in the automotive sector. Our housings are either completely enclosed or sealed in such a way that moisture can no longer penetrate here. This ensures that the electronic components, including the LED, the circuit board and control electronics cannot be damaged by moisture.

There are even special illuminators that you can submerge under water without any damage.

As a manufacturer and specialized dealer in the field of professional LED automotive lighting, we have a wide range of different illuminants, work lights or headlights. Please pay close attention to the item description when choosing a product, because not all working lights (illuminations) can be mounted on every and every vehicle, this is due to legislation. Even if it is theoretically possible to build a truck exterior lighting on a normal private motor vehicle, this may then no longer be permitted in public road traffic.

In our product range you will find a variety of LED lighting for the areas of motor vehicles, ATVs, quads, trucks, motorcycles, buses, boats or other means of transportation that run either on fossil fuels or purely electric.

For returns that are not related to a complaint, you pay the return shipping costs. You can find everything else in our Revocation conditions take.

Once we have received the goods, the refund will always be made in the same way as the original payment. For more details you can refer to the Cancellation policy take.

If you have entered your shipping address incorrectly or want to change the address for delivery, it is best to write us an email or use our contact form. If you have already received a shipping confirmation, it may no longer be possible to change the address. However, feel free to contact us and we will still try to pass on the change.

Nice that you ask, yes of course we send some goods by freight forwarding, because they are simply too heavy or too large for regular parcel shipping. You can see the shipping costs in the shopping cart by entering your ZIP code (postal code) or on the shipping information page. However, make sure you have at least one item in your shopping cart beforehand so that the store can calculate the shipping costs correctly based on the item.

If we send you goods that are too large or too heavy for regular parcel shipping and they are then sent to you by a freight forwarder, we would like to draw your attention to 1-2 procedures.

Before delivery or already during the ordering process, please be sure to provide a mobile phone number, this is very important for the carrier for delivery. You will then receive to your order a period of 2 to 3 days for delivery. The carrier will then contact you on the day of delivery in time for you to be there.

If you are interested in the general shipping costs, you can view them in the shopping cart by entering your zip code (postal code) or on the shipping information page. However, make sure you have at least one item in your shopping cart beforehand so that the store can calculate the shipping costs correctly based on the item.

If you think that your issue is a warranty case, please contact us either via our online contact form or write an email directly to and with all relevant information for us, such as your customer number, the invoice number, if necessary pictures of the problem and a small problem description.

Nice that you ask, as a professional manufacturer in the field of winches and automotive goods, as well as other trades and as a specialized dealer for the products offered in our online store, we offer a range of services with. Among other things, we naturally take care of the pure shipping of our goods, a clean and fast complaint handling, but also repairs in case of defects, complete replacement or, if necessary, customization requests, but these only on request.

In addition to the obvious service, we also offer our dealers the option of dropshipping, so they can work with us to expand your storage capacity and corresponding customer base. If you have a service request, you can always contact us by phone at the following number or you can write us an email, either through our contact form or directly through your own email program e.g. on your cell phone.

No matter what your request is, you can contact us at the locations listed below. Please also read the section below "What do I have to consider when filing an RMA?".

This depends entirely on whether, for example, the winch or a generator can still be repaired. If this is not the case and we, as manufacturer and specialist dealer, have to destroy the goods because they are no longer repairable, then you will receive an appropriate replacement device, provided the defect still occurs within the statutory warranty obligation or the warranty given by us.

Important!

However, if we determine that the damage was caused intentionally, there are two options, either we send the product back to you unrepaired or you agree with us on a professional repair, because an obvious damage, for example, is not covered by the statutory warranty or the warranty.

You can find more information about this of course under the section revocation and in our terms and conditions.

Nice that you ask, before you report a complaint case to us, we ask you to contact us before briefly by phone, so that we can create your case already. You will then receive a complaint number (RMA number for short) from us, which you specify in further communication with us.

If it should be necessary that we need some pictures and further information from you beforehand, we will already inform you about this during the conversation on the phone. In this case, please send us an e-mail to service@winschindustrie.com. Please enter your data, the complaint number (RMA No.) and describe the problem in detail. If it is really a service case, you will receive a return label from us.

With the receipt of the return label, you pack the goods again in the original box and send it back with the return label and very important, with the complaint number and your letter to us that you have already sent us by e-mail. This is important so that we can immediately identify your shipment when we receive it, which allows us to speed up the process.

Depending on the complexity, a repair takes between one and two weeks. If all spare parts are in stock, even faster if necessary. In the meantime, if you have any questions about the status of your repair, you can do so by phone or email, quoting your RMA number.

A normal repair usually takes one to two weeks, as long as the spare parts are in stock. If the repair is delayed, we will inform you in time. During the repair you can ask for the status of your repair at any time by stating your RMA number.

Please refrain from asking for the status of your repair every day.

Of course. As a professional manufacturer and specialist seller, we even ask for it, because it is our personal concern that you have something from your device for as long as possible. You do not always have to buy new, many of our products can be quickly and easily repaired. To do this, you can contact us either via our store page, by phone or directly by e-mail. Here you describe us then your request. However, it is advisable to make a short phone call, so that we already know roughly what it is about, everything else will then explain to you the employee on the phone.

As a rule, when we open a claim, we always send you an appropriate shipping label. So you do not need to do anything. In the case of a forwarding shipment, we will also organize the pickup for you, you just need to be on site on the appropriate day and time, because a pickup by forwarding is still associated with significant costs.

However, you are free to choose your own shipping service provider of your choice, in which case we can no longer bear the costs. However, we recommend for a fast processing to use our shipping label, for this we use the DHL.

Gladly. You have the possibility to bring the goods/device by us at any time. However, before you visit us, we ask you to give us a short call so that we can provide you with an RMA number, then the processing on site is done quickly for you and you can devote yourself to more important things. You can get the RMA number from our staff either by phone or by mail.

Of course, we also offer spare parts for your devices. As a manufacturer, but also as a specialist dealer, we always have many spare parts in stock. You will find the spare part numbers either in your manual, which you may have already downloaded, or directly in our store at the article in our spare parts list. If you have neither a spare parts list or instructions, you can also send a general request, with photos to the thing, by e-mail to us, we will see what we can do.

Spare parts can be obtained directly from us, please contact us by e-mail with the spare part number, which you will find either in the manual or the spare parts list. If you do not find a number in the manual or the spare parts list, please send us an e-mail with a meaningful photo and a short description of the problem.